Rechercher

Accueil > La Recherche > Axes & Equipes > Matière Molle & Verres > Equipe : Physique des Verres > Thème : Mécanismes d’endommagement des verres à l’échelle nanométrique

Plasticity and densification

publié le , mis à jour le

Involved researchers : M. Foret, B. Hehlen, B. Rufflé, H. Tran (PhD), C. Weigel

Because of their dominant brittle character, glasses experience plasticity only under high pressure or high stress concentration conditions. In practice, the reference case corresponds to the situation of the mechanical contact. The plastic properties of glasses thus condition their resistance to surface damage. For reasons which are both theoretical (the absence of a crystalline lattice does not allow the use of dislocations to explain plasticity) and practical (the micrometric scale of the plastic zone makes difficult the measurements of deformations) the plastic behaviour remains ill understood. The plastic flow is thus accompanied by an irreversible densification process. Glasses are furthermore subjected to a mechanical ageing effect, i.e. hardening : the plastic criterion depends on the history of mechanical loading.

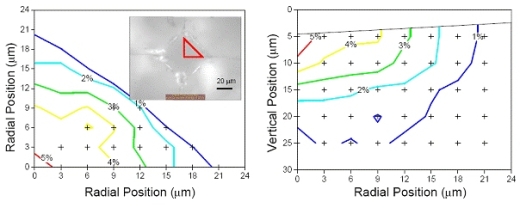

Vibrational spectroscopies have proven for long to be a very good tool for studying the medium range order glass structure. The recent availability of these techniques at the micrometric scale allows them to extend their range of applications. We have make use of high resolution μ-Brillouin spectroscopy to study the effect of plastic deformation on the glass structure and to progress toward the identification of the plastic constitutive law for glasses.

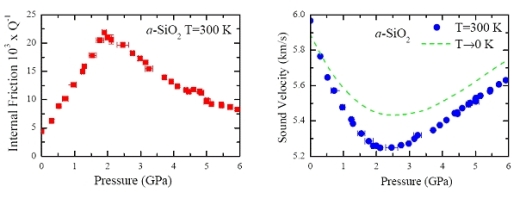

New accurate Brillouin data in v-SiO2 under hydrostatic pressure at room T in the range 0 – 6 GPa have been obtained. No irreversible changes are observed in this pressure range, neither in velocity nor in absorption. As already well-reported, the pressure dependence of the velocity shows a pronounced minimum slightly above 2 GPa. Most interesting, the absorption exhibits a dramatic rise under pressure and passes through a maximum nearly at the same pressure value, ~ 2 GPa. The results are analyzed on the basis of the pressure dependence of the relaxing defects.